Inventory Management and Workflow: The Perfect Pairing

Executing the steps to achieve an accurate, organized warehouse is one of the best actions you can take to ensure a successful business. The goal is clear, but it’s getting there that makes things complicated. Luckily, we have plenty of advice on how to upgrade your inventory management.

Wave goodbye to human error

Your greatest asset in the warehouse can also be the source of your downfall—your employees. With the right atmosphere and tools, your warehouse crew is capable of great feats of accuracy, but they’re still human. Unfortunately, your workers are bound to make some mistakes. And the more manual your order fulfillment processes are, the more susceptible you are to these mix-ups.

A huge part of reducing inaccuracies in inventory management is achieved by first providing your employees with better tools. There are a handful of ways you can go about doing that, but implementing reliable technology is a great first step in the right direction.

Enter barcoding

Behold, barcoding, the very technology your warehouse could be missing! For those who aren’t familiar, barcoding is the process of assigning easily scannable images to every piece of stock in your warehouse. The image, or barcode, houses encrypted information about that item. This way, all you have to do is scan the item, and the necessary information is collected. Say goodbye to clipboards, sticky notes, and random Excel documents. Barcoding makes tracking and ensuring the accuracy of your orders a one-step process.

When you implement barcodes, you have much quicker access to information that previously took ages to find and update. There’s also the added bonus that this information can assist your workers beyond the physical picking process. With barcoding in place, you can easily scan and validate that you have the correct item, mark it off the order so other employees know it’s been picked, and update your inventory count for up-to-the-minute accuracy that won’t throw a wrench in the accuracy of your listings elsewhere.

Barcoding also comes in handy for receiving inventory, moving inventory across multiple locations, and stock counts. Complete all the goods movement transactions, and never let inventory slip through the cracks.

See you never, bottlenecks

As we know, human error alone can’t account for everything that goes wrong in the warehouse. We can’t forget about one of the greatest threats to your accuracy—bottlenecks. We often discuss how bottlenecks are the enemy of efficiency, halting processes and causing unnecessary gaps in production. However, those inefficiencies don’t just slow down your customer-to-cash cycle. They also invite more chances for miscommunication, a breeding ground for mix-ups in your order fulfillment process. Most of your current bottlenecks are likely fueled by poorly optimized processes. Luckily, there are plenty of tools at your disposal to amend that.

Get accurate with workflows

When we think of “accuracy” in inventory management, our minds often jump to the picking process where the wrong item gets packed or is completely forgotten. However, inaccuracies can occur at any point in your fulfillment process. These errors can sneak up on you anywhere, in the form of missed steps, wonky barcodes, or entire packages and bins getting mixed up or lost. These steps are all related to the “process” rather than just picking alone, which means you need a broader, more powerful tool to help combat that. This is where workflow becomes especially handy.

Workflow not only establishes a precedent for your process. It also ensures that more complicated orders can be fulfilled without hassle or mistakes. Your workflow is the ultimate productivity flow chart. It’s a widely-circulated, universally-trusted system for completing your order-to-cash cycle. With it, all your employees are on the same page. They can also easily retrace their steps if something does go awry.

Track every order at every stage

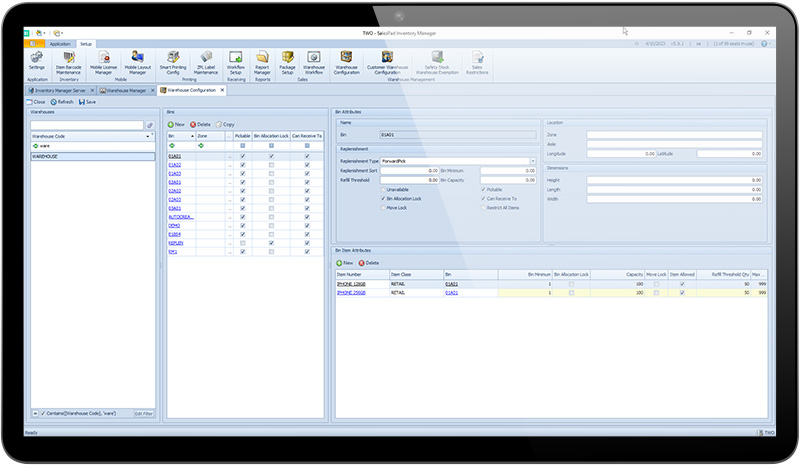

Separately, barcoding and workflows can do a lot of good for your operation. But together, you’ll have the peace of mind of knowing that your data is accurate, coupled with a clear bird’s eye view of your entire inventory across all locations. Luckily, Cavallo provides both of these powerful tools in the form of Inventory Manager and Workflow & Profit Manager. And the best part: these two products integrate seamlessly with each other to make your warehouse an easily navigable space and your customer-to-cash cycle a smooth process.

When paired with barcoding, Inventory Manager ensures accurate item, packing, and shipping data for every order you receive from your vendors and send out to your customers. Instead of manually copying long SKUs or opening each package to make sure it’s labeled correctly, scan barcodes in seconds with Inventory Manager. Go from blindly wandering the aisles of your warehouse to knowing where each piece of inventory is located.

When bottlenecks threaten to delay shipping, what once would have been a precursor to inevitable customer dissatisfaction can now be resolved through Workflow & Profit Manager. Instantly see all your orders, which workflow queue they’re in, and where they’re getting stuck. Total visibility into your operation is a game-changer. With the view that Workflow & Profit Manager provides, you can allocate your resources to counteract delays in your picking, packing, and shipping processes, and make sure all your orders get out on time.

A note on accuracy and customer satisfaction

The drawbacks to making mistakes in your warehouse are obvious, but there’s a direct line between mixing up orders and losing money for your company. The biggest threat to your overall profitability comes when your customer returns an item. In the age of online superstores like Amazon, speed and convenience are kings. Your customers expect to get things easily, and they don’t have much patience for bumps in the road. By implementing more strategies to ensure the accuracy of the orders you ship out, you’re actively investing in the future of your company.

The key to maintaining positive relationships with your customers is ensuring they can trust you to deliver what they need. Of course, creating that experience takes more than just an accurate picking process. A great business strategy starts in your warehouse, so it’s essential that you’ve optimized this sector as much as possible. Your warehouse holds huge productivity potential, you just need the tools to activate it—tools we’re happy to provide.

Get in touch with us to see Inventory Manager and Workflow & Profit Manager in action, and learn how you can change the game with your inventory management tools. If you want to dive deeper into our AI-powered solutions for distributors, Cavallo’s Order Intelligence Platform can help your business unlock hidden profits and execute perfect orders at scale by pairing with your ERP.